MLIP Phase Change Memory: From Materials Science to Transformative Biomedical Applications

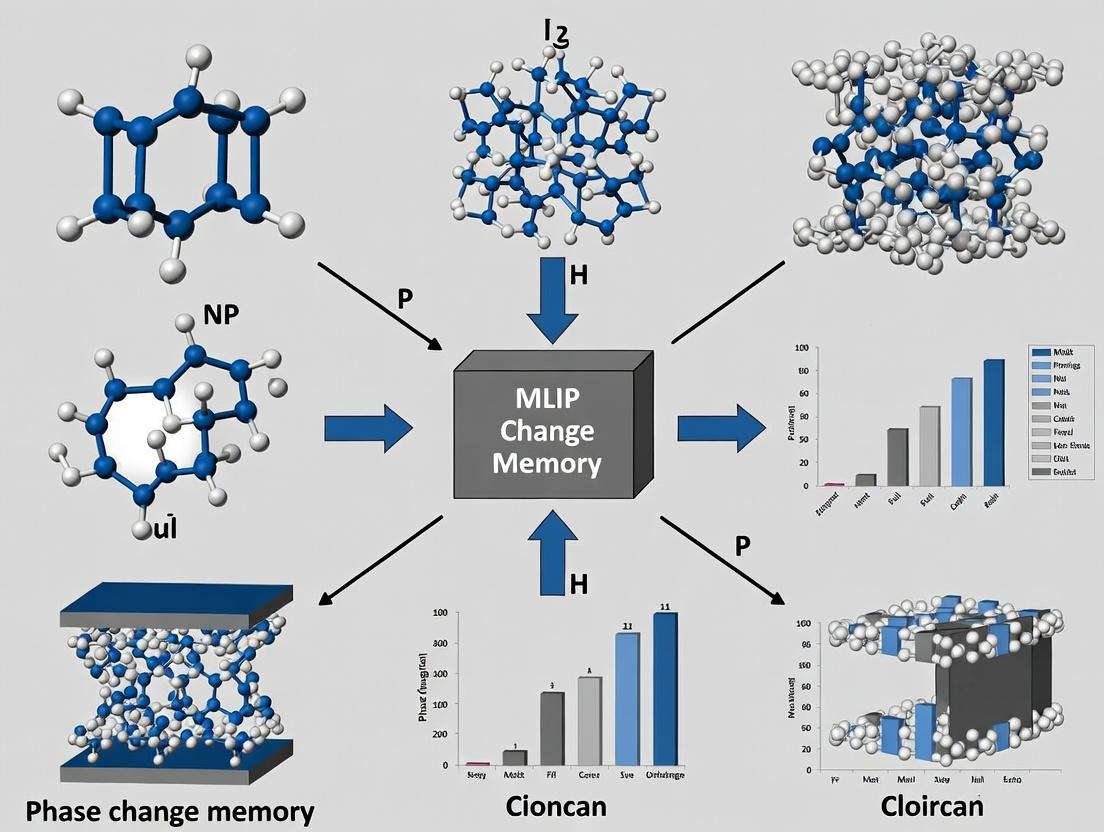

This article explores the application of Machine Learning Interatomic Potentials (MLIPs) in accelerating the discovery and optimization of Phase Change Memory (PCM) materials, with a focus on implications for biomedical...

MLIP Phase Change Memory: From Materials Science to Transformative Biomedical Applications

Abstract

This article explores the application of Machine Learning Interatomic Potentials (MLIPs) in accelerating the discovery and optimization of Phase Change Memory (PCM) materials, with a focus on implications for biomedical research and drug development. We cover the foundational principles of MLIPs and PCM, detail methodologies for materials screening and property prediction, address key challenges in model training and experimental validation, and evaluate MLIP performance against traditional computational methods. The synthesis provides a roadmap for researchers to leverage this powerful computational paradigm for developing next-generation biocompatible memory devices and high-throughput biomolecular simulation platforms.

Understanding the Core: MLIP Fundamentals and PCM Material Science for Biomedical Researchers

Machine Learning Interatomic Potentials (MLIPs) represent a paradigm shift in the computational design and discovery of Phase Change Materials (PCMs), particularly for advanced memory applications. Traditional simulation methods, like Density Functional Theory (DFT), offer high accuracy but are computationally prohibitive for the timescales and system sizes required to model nucleation, amorphous-crystalline transitions, and defect dynamics in PCMs. Conversely, classical force fields are fast but lack the quantum-mechanical accuracy necessary to predict electronic properties crucial for memory switching.

MLIPs bridge this gap by training neural networks on high-fidelity DFT data, achieving near-DFT accuracy at a fraction of the computational cost. This enables ab initio molecular dynamics (AIMD) simulations over nanoseconds for thousands of atoms, allowing researchers to probe:

- Crystallization Mechanisms: Atomistic pathways of crystal growth from the amorphous phase.

- Glass Formation Kinetics: Quenching dynamics and the nature of the glassy state.

- Defect Engineering: Role of vacancies, dopants, and interfaces on switching speed and data retention.

- Multi-Component Systems: Exploration of novel ternary and quaternary chalcogenide alloys (e.g., Ge-Sb-Te, Ag-In-Sb-Te) beyond simple binaries.

Key Quantitative Advantages of MLIPs over Traditional Methods

Table 1: Performance & Accuracy Comparison of Simulation Methods for PCMs

| Metric | Density Functional Theory (DFT) | Classical Force Fields (FF) | Machine Learning Interatomic Potentials (MLIP) |

|---|---|---|---|

| Accuracy (vs. Experiment) | High (1-5% error on lattice params) | Low to Medium (Highly system-dependent) | Very High (Approaches DFT fidelity) |

| Typical System Size | 100-1,000 atoms | 10^4 - 10^6 atoms | 1,000 - 100,000 atoms |

| Accessible Timescale | Picoseconds to nanoseconds | Nanoseconds to microseconds | Nanoseconds to microseconds |

| Computational Cost (Relative) | 10,000x | 1x | 10-100x (vs. FF) |

| Property Prediction | Energetics, electronic structure, phonons | Structure, basic thermodynamics | Energetics, structure, dynamics, some electronic features |

| Transferability | Universal | Narrow, system-specific | Good within trained chemical space |

Detailed Experimental Protocols

This section outlines core protocols for generating and utilizing MLIPs in PCM research, framed within a thesis on MLIP-driven PCM discovery for phase-change memory.

Protocol 2.1: Generating a Training Dataset via Active Learning

Objective: To create a robust, diverse, and minimally sized DFT dataset that captures the relevant configurational space of a target PCM (e.g., Geâ‚‚Sbâ‚‚Teâ‚… - GST225).

Materials & Software:

- Software: VASP/Quantum ESPRESSO (DFT), LAMMPS/PyLAMMPS (MD), FLARE or ALKEMIE (active learning platform).

- Initial Structures: Crystalline GST225 cells, amorphous GST225 models (from melt-quench), surfaces, defect-containing cells.

Methodology:

- Initial Seed Calculation: Perform AIMD simulations at multiple state points (e.g., 300 K, 600 K, 900 K, 1200 K) for small (e.g., 216-atom) systems of crystalline and amorphous phases. Extract ~100-200 snapshots.

- Active Learning Loop: a. Train an initial MLIP (e.g., Neural Network Potential, Gaussian Approximation Potential) on the current dataset. b. Deploy the MLIP to run exploratory MD simulations: melt-quench cycles, crystal growth from the melt, ion bombardment to create defects. c. Use an uncertainty quantifier (e.g., committee disagreement, variance) to identify configurations where the MLIP prediction is uncertain. d. Select the top N (e.g., 10-20) most uncertain configurations and compute their energies/forces using DFT. e. Add these new labeled data points to the training set.

- Convergence Check: Repeat Step 2 until the MLIP's uncertainty falls below a pre-defined threshold across a wide range of simulated properties (e.g., radial distribution function, mean square displacement, energy distributions) for validation structures not included in training.

- Final Training: Retrain the MLIP on the complete, converged dataset.

Protocol 2.2: Simulating Phase Transition Kinetics

Objective: To simulate the temperature-driven amorphous-to-crystalline transition and extract nucleation rates and growth velocities.

Materials & Software: Trained MLIP for target PCM, LAMMPS software, OVITO for visualization/analysis.

Methodology:

- Prepare Amorphous Sample: Using the trained MLIP, heat a crystalline system above its melting point (e.g., 1500 K for GST225), hold, then quench rapidly (e.g., 10^14 K/s) to 300 K to generate a relaxed amorphous model (~10,000 atoms).

- Isothermal Crystallization: Heat the amorphous model to a target crystallization temperature (T_x, e.g., 450 K, 500 K, 550 K). Perform constant-temperature, constant-pressure (NPT) MD for 50-200 ns, saving trajectories frequently.

- Order Parameter Analysis: Use structural order parameters (e.g., Stein & Nelson's "Crystal Recognition" bond-order parameters, tetrahedrality index) within OVITO or custom scripts to distinguish crystalline (cubic/hexagonal) atoms from amorphous atoms in each snapshot.

- Nucleation & Growth Metrics: a. Nucleation Rate: Track the number of crystalline nuclei (clusters > a critical size) as a function of time. The slope of the linear regime gives the nucleation rate. b. Growth Velocity: Measure the increase in radius of the largest crystalline cluster over time. The slope is the linear growth velocity.

- Repeat: Conduct simulations at multiple T_x to map the temperature-dependence of kinetics, enabling comparison with laser-induced switching experiments.

Visualizations

Active Learning Loop for MLIP Training

PCM Crystallization Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Computational Materials & Tools for MLIP-PCM Research

| Item / Software | Category | Primary Function in MLIP-PCM Workflow |

|---|---|---|

| VASP / Quantum ESPRESSO | Ab Initio Software | Generates the high-accuracy reference data (energies, forces, stresses) for training MLIPs. Essential for electronic property calculation. |

| LAMMPS | Molecular Dynamics Engine | The primary platform for running large-scale MD simulations using fitted MLIPs to study phase transitions, mechanical properties, and thermal transport. |

| PyLAMMPS / ASE | Scripting Interfaces | Python wrappers that enable seamless integration of MLIP inference, on-the-fly analysis, and automated workflow management within LAMMPS simulations. |

| FLARE / ALKEMIE | Active Learning Platform | Specialized software that automates the active learning loop: training MLIPs, running exploratory MD, querying uncertainties, and managing DFT calls. |

| NequIP / MACE / GAP | MLIP Architectures | Specific machine learning models for representing interatomic potentials. Offer different trade-offs in accuracy, speed, and data efficiency. |

| OVITO | Visualization & Analysis | Critical for visualizing atomic trajectories, identifying phases via order parameters, and quantifying microstructural evolution during simulations. |

| High-Performance Computing (HPC) Cluster | Infrastructure | Required for both the DFT data generation steps and the subsequent large-scale, long-timescale production MD simulations using MLIPs. |

| 2,2,7-Trimethyloctane | 2,2,7-Trimethyloctane|C11H24|CAS 62016-29-9 | |

| 2,3-Dimethyl-4-propylheptane | 2,3-Dimethyl-4-propylheptane, CAS:62185-30-2, MF:C12H26, MW:170.33 g/mol | Chemical Reagent |

Phase-change memory (PCM) leverages the rapid, reversible switching of chalcogenide alloys between amorphous (high-resistance) and crystalline (low-resistance) states. Within the broader thesis on Machine Learning Interatomic Potential (MLIP) for PCM materials, understanding the precise experimental landscape of these alloys is critical for generating and validating high-fidelity training data. This document provides application notes and standardized protocols for key experiments characterizing PCM materials like Ge-Sb-Te (GST) and Sb₂Te₃, aimed at accelerating MLIP-guided material discovery and optimization for next-generation memory and neuromorphic applications.

Key Material Properties & Quantitative Data

Table 1: Fundamental Properties of Primary Chalcogenide Alloys

| Material | Crystalline Phase | Resistivity (Ω·cm) Amorphous | Resistivity (Ω·cm) Crystalline | Melting Point (°C) | Crystallization Temperature (°C) | Band Gap (eV) Amorphous | Band Gap (eV) Crystalline |

|---|---|---|---|---|---|---|---|

| Geâ‚‚Sbâ‚‚Teâ‚… (GST-225) | Rocksalt (Fm-3m) | ~10âµ | ~10â»Â³ | ~600 | ~150-200 | ~0.7-0.8 | ~0.5 |

| Sbâ‚‚Te₃ | Trigonal (R-3m) | ~10â»Â¹ | ~10â»â´ | ~620 | ~100-150 | ~0.3 | ~0.2 |

| GeTe | Rocksalt (Fm-3m) / Rhombohedral | ~10² | ~10â»Â³ | ~725 | ~180-220 | ~0.8 | ~0.6 |

| Ag-In-Sb-Te (AIST) | Rocksalt / Hexagonal | ~10³ | ~10â»Â³ | ~550-600 | ~120-180 | ~0.7-1.0 | ~0.5-0.7 |

Table 2: Device Performance Metrics for PCM

| Metric | Ge₂Sb₂Te₅ | Sb₂Te₃ | Ideal Target for MLIP-Optimized Materials |

|---|---|---|---|

| SET Speed | ~50-100 ns | ~10-30 ns | < 10 ns |

| RESET Energy (per bit) | ~10-100 pJ | ~5-50 pJ | < 1 pJ |

| Endurance | ~10ⶠ- 10⹠cycles | ~10ⵠ- 10⸠cycles | > 10¹² cycles |

| Data Retention (at 85°C) | > 10 years | ~1-5 years | > 10 years at 150°C |

| Resistance Ratio (Râ‚/R꜀) | 10³ - 10âµ | 10² - 10â´ | > 10âµ |

Experimental Protocols

Protocol 1: Thin Film Deposition & Structural Characterization for MLIP Training Data Generation

Objective: To prepare uniform chalcogenide thin films and characterize their as-deposited structural state for correlation with atomic-scale simulations.

Materials: See "The Scientist's Toolkit" (Section 5).

Methodology:

- Substrate Preparation: Clean 4-inch SiO₂/Si wafers via RCA-1 cleaning. Dehydrate at 150°C for 5 minutes in N₂ ambient.

- Sputtering Deposition: a. Load target (e.g., Geâ‚‚Sbâ‚‚Teâ‚…) and substrate into magnetron sputtering chamber. b. Pump down to base pressure ≤ 5.0 x 10â»â· Torr. c. Introduce Ar gas at 20 sccm, maintaining working pressure of 3 mTorr. d. Pre-sputter target for 5 minutes with shutter closed. e. Deposit film at 30 W RF power for 300 seconds to achieve ~100 nm thickness (calibrated via profilometer). f. Anneal in-situ at 250°C for 2 minutes (for crystalline films) or cool immediately (for amorphous films).

- Structural Analysis (XRD): a. Perform θ-2θ scan using Cu Kα source (λ = 1.5406 Å). b. Range: 20° to 60°, step size 0.02°, dwell time 2 s/step. c. For amorphous verification, look for broad halo (~27-33°). For crystalline, identify peaks (GST rocksalt: (200) ~29°, (220) ~43°).

- Compositional Verification (EDS/XPS): a. Acquire EDS spectrum at 10 kV accelerating voltage. b. Quantify peak areas for Ge Lα, Sb Lα, Te Lα lines using standardless ZAF correction. c. Target stoichiometry within ±2 at.% deviation.

Protocol 2:In-SituResistivity-Temperature Measurement for Phase Transition Kinetics

Objective: To quantitatively measure the temperature-dependent resistivity and crystallization kinetics, providing key validation data for MLIP-predicted phase stability.

Materials: See "The Scientist's Toolkit" (Section 5).

Methodology:

- Device Fabrication: Photolithographically define a 4-point probe structure on deposited film. Evaporate Ti/Au (10/100 nm) contacts.

- Setup: Mount sample in vacuum probe station (P < 10â»âµ Torr) with a calibrated resistive heater.

- Measurement: a. Ramp temperature from 25°C to 350°C at a constant rate of 10°C/min. b. Measure resistance in-situ using a source-measure unit (SMU) in 4-wire mode with a constant current (I = 10 µA) to avoid Joule heating. c. Record resistance (R) and temperature (T) synchronously.

- Data Analysis: a. Plot log(Resistivity) vs. Temperature. b. Identify Tᶜ (crystallization temperature) at the point of inflection. c. Extract activation energy for crystallization (Eâ‚) using the Kissinger method by repeating measurement at different heating rates (5, 10, 20°C/min) and plotting ln(β/Tᶜ²) vs. 1/(kBTᶜ).

Visualizations

Diagram Title: MLIP-Experimental Feedback Loop for PCM Development

Diagram Title: PCM RESET and SET Switching Mechanism

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PCM Experimental Research

| Item / Reagent | Function & Application | Key Specification / Notes |

|---|---|---|

| Geâ‚‚Sbâ‚‚Teâ‚… Sputtering Target | Source material for thin film deposition. | 99.999% purity, 3-inch diameter, bonded. Stoichiometry certified. |

| SiOâ‚‚/Si Wafer | Standard substrate for film growth and device fabrication. | <100> orientation, 500 nm thermal oxide. |

| AZ 5214E Photoresist | For lithographic patterning of PCM device cells or electrodes. | Image reversal capability for clean lift-off. |

| Ti/Au Evaporation Pellets | Deposition of low-resistance, adherent electrical contacts. | Ti: 99.995%, Au: 99.999%. |

| Tetramethylammonium Hydroxide (TMAH) Developer | Develops exposed photoresist for patterning. | 2.38% solution for precise development. |

| Argon Gas | Sputtering process gas for film deposition. | 99.9999% (6N) purity to prevent film contamination. |

| Deionized Water | Substrate cleaning and rinsing in lithography. | Resistivity ≥ 18.2 MΩ·cm. |

| Calibrated HR-2000 Heater | For in-situ thermal annealing and resistivity-temperature measurements. | Temperature range RT-500°C, stability ±0.5°C. |

| Cu Kα X-ray Source | For XRD analysis of film crystallinity and phase identification. | Wavelength λ = 1.5406 Å. |

| Source-Measure Unit (SMU) | For precise electrical characterization (I-V, R-T). | Example: Keithley 2450, capable of 4-wire sensing. |

| 1,3-Dimethyl-2-propoxybenzene | 1,3-Dimethyl-2-propoxybenzene, CAS:61144-80-7, MF:C11H16O, MW:164.24 g/mol | Chemical Reagent |

| 2,2,3,3,4,4-Hexamethylpentane | 2,2,3,3,4,4-Hexamethylpentane, CAS:60302-27-4, MF:C11H24, MW:156.31 g/mol | Chemical Reagent |

Application Notes: The PCM Modeling Paradigm Challenge

The research of Phase Change Memory (PCM) materials, such as Ge-Sb-Te (GST) alloys, is fundamentally constrained by the computational trade-offs between accuracy and scale. Density Functional Theory (DFT) provides high-fidelity electronic structure insights but is limited to ~1000 atoms and picosecond timescales. Classical empirical potentials (e.g., Tersoff, SW) enable larger molecular dynamics simulations but suffer from poor transferability and inaccurate description of the covalent-metallic bonding transition central to the phase change phenomenon. This bottleneck directly impedes the rational design of next-generation PCM materials for non-volatile memory and neuromorphic computing applications within our broader MLIP-driven thesis.

Table 1: Quantitative Comparison of Computational Methods for PCM Research

| Method | Typical System Size | Time Scale | Accuracy (Formation Energy) | Cost (CPU-hr/atom*ps) | Key Limitation for PCM |

|---|---|---|---|---|---|

| DFT (e.g., SCAN meta-GGA) | 100 - 1,000 atoms | < 100 ps | High (±0.05 eV/atom) | 10,000 - 100,000 | Cannot simulate nucleation, grain growth, or device-scale effects. |

| Classical Potentials (e.g., Tersoff) | 10^4 - 10^7 atoms | ns - µs | Low (±0.5 eV/atom) | 0.1 - 10 | Fails to reproduce resistivity contrast, electronic properties, and phase transition kinetics accurately. |

| Machine Learning Interatomic Potentials (MLIP) | 10^3 - 10^6 atoms | ns - µs | Near-DFT (±0.1 eV/atom) | 10 - 1,000 (Training: ~10^4 DFT CPU-hr) | Initial training data generation and active learning cycle are resource-intensive. |

Experimental Protocols

Protocol 2.1: Benchmarking DFT Functionals for GST Phase Energetics

Objective: To evaluate the accuracy of various DFT exchange-correlation functionals in predicting the formation energy difference between crystalline (cubic) and amorphous GST-225, the critical metric for PCM switching energy.

Materials & Software:

- Software: VASP (Vienna Ab initio Simulation Package) or Quantum ESPRESSO.

- System: Geâ‚‚Sbâ‚‚Teâ‚… (GST-225) supercell (e.g., 3x3x3 cubic rock salt, 405 atoms).

- Functionals to Test: PBE, PBEsol, SCAN, rSCAN.

Procedure:

- Structure Generation: Generate atomic coordinates for crystalline GST-225 in the cubic phase. Create an amorphous model via DFT-based melt-quench (heat to 2000K, equilibrate, quench to 300K at >10 K/ps).

- DFT Calculations: a. Perform full geometry relaxation (ionic + cell) for both phases using each functional. b. Use consistent settings: PAW pseudopotentials, 400 eV plane-wave cutoff, k-point spacing ≤ 0.03 Ã…â»Â¹, electronic convergence 10â»â¶ eV.

- Data Analysis: a. Calculate total energy (Ecryst, Eamorph) from relaxed structures. b. Compute formation energy ΔE = Eamorph - Ecryst (per atom). c. Compare results across functionals. The SCAN meta-GGA functional is expected to yield the most accurate ΔE compared to experimental estimates (~0.2-0.3 eV/atom).

Protocol 2.2: Validation of Classical Potential for Melt-Quench Simulation

Objective: To assess the reliability of a classical potential (e.g., Tersoff) in reproducing the radial distribution function (RDF) and coordination numbers of amorphous GST obtained from DFT.

Materials & Software:

- Software: LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator).

- Potential: Parameterized Tersoff potential for Ge-Sb-Te systems.

- Reference Data: DFT-calculated amorphous structure from Protocol 2.1.

Procedure:

- Simulation Setup: Initialize a 4096-atom GST-225 model in the crystalline phase within LAMMPS.

- Melt-Quench MD: a. Equilibrate at 300K for 50 ps (NPT ensemble). b. Heat to 2000K over 100 ps and hold for 100 ps to melt. c. Quench to 300K at a rate of 20 K/ps (NVT ensemble). d. Equilibrate at 300K for 50 ps.

- Structural Analysis: a. Compute the partial RDFs (Ge-Te, Sb-Te, Te-Te) for the final amorphous snapshot. b. Calculate the average coordination numbers by integrating the first peak of the RDFs.

- Benchmarking: Plot the RDFs and coordination numbers against the reference DFT data. Significant peak shifting or coordination errors (>10%) indicate poor potential transferability.

Visualizations

Title: The Computational Bottleneck & MLIP Solution

Title: Traditional PCM Simulation Workflow & Validation Loop

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Computational Tools for PCM Materials Research

| Item/Category | Example(s) | Primary Function in PCM Research |

|---|---|---|

| Ab Initio Software | VASP, Quantum ESPRESSO, ABINIT, CASTEP | Performs DFT calculations to generate accurate reference data for electronic structure, phase energies, and small-scale MD. |

| Classical MD Engine | LAMMPS, GROMACS, HOOMD-blue | Enables large-scale (atomistic to mesoscale) molecular dynamics simulations using empirical or ML potentials. |

| Empirical Potentials | Tersoff (Si/Ge), Stillinger-Weber, EDIP | Provides fast force calculations for specific bonding environments; often pre-parameterized for elements in PCMs. |

| MLIP Framework | AMPTorch, DeepMD-kit, MACE, NequIP | Software to train, validate, and deploy machine-learned potentials that bridge DFT accuracy and MD scale. |

| Structure Analysis | OVITO, VMD, pymatgen, ASE | Visualizes atomic trajectories and analyzes key metrics (RDF, coordination, diffusivity, nucleation). |

| High-Performance Computing (HPC) | CPU Clusters, GPU Accelerators (NVIDIA, AMD) | Essential computational resource for all stages, from DFT data generation to production MLIP-MD runs. |

| 2,3-Dibromo-2-methylpentane | 2,3-Dibromo-2-methylpentane|CAS 54305-88-3 | |

| beta-D-Glucose 1-phosphate | Beta-D-Glucose 1-phosphate|High-Purity Research Chemical | High-purity Beta-D-Glucose 1-phosphate for research applications. This product is For Research Use Only (RUO) and is not intended for diagnostic or personal use. |

Within the context of a broader thesis on MLIPs for phase change memory (PCM) materials application research, selecting the foundational machine learning architecture is critical. This document details the core principles, application notes, and experimental protocols for Neural Network (NN) and Gaussian Process (GP) based interatomic potentials, focusing on their utility for modeling chalcogenide alloys like GeSbTe.

Theoretical Framework: NN vs. GP for MLIPs

Core Architectural Principles

| Feature | Neural Network Potentials (e.g., Behler-Parrinello, ANI, NequIP) | Gaussian Process Potentials |

|---|---|---|

| Mathematical Foundation | Parametric function approximator (non-linear transformations). | Non-parametric, Bayesian kernel-based regression. |

| Data Efficiency | Lower; requires large datasets (>1000s configurations). | Higher; can provide accurate models with hundreds of data points. |

| Extrapolation Warning | Poor; unpredictable behavior far from training data. | Quantified; predictive uncertainty increases in sparse regions. |

| Computational Cost | Training: High. Inference: Very Low (fast evaluation). | Training: O(N³) scaling with data. Inference: Slower than NNs. |

| Representation Power | High-capacity models for complex, high-dimensional mappings. | Flexible but limited by kernel choice and scaling. |

| Output Uncertainty | Not intrinsically provided (requires ensembles/dropout). | Intrinsic probabilistic uncertainty from posterior distribution. |

Key Quantitative Performance Metrics (Hypothetical PCM Study)

Table 1: Representative performance metrics on a benchmark Geâ‚‚Sbâ‚‚Teâ‚… dataset.

| Metric | NN Potential (4-layer, 128 nodes) | GP Potential (SOAP kernel) | Notes |

|---|---|---|---|

| Energy MAE (meV/atom) | 1.8 - 3.5 | 1.0 - 2.0 | On held-out test set. |

| Force MAE (meV/Ã…) | 80 - 120 | 60 - 100 | Critical for MD stability. |

| Inference Time (ms/atom/step) | ~0.05 | ~1.2 | Single CPU core. |

| Training Data Required | ~10,000 configs. | ~1,000 configs. | For same target accuracy. |

| Uncertainty Correlation | Low (estimated) | High (explicit) | With prediction error. |

Experimental Protocols

Protocol 2.1: Generating a Training Dataset for PCM Materials

Objective: Create a robust, diverse ab initio dataset for training MLIPs.

- Initial Structure Collection: Gather crystal structures (cubic/hexagonal GeSbTe), amorphous models (from melt-quench), and defect-containing slabs.

- Active Learning Loop: a. Initialize with 50-100 DFT configurations. b. Train preliminary MLIP (GP recommended for initial loop due to uncertainty). c. Run molecular dynamics (MD) or structure searches using the MLIP. d. Use the MLIP's uncertainty (GP) or committee disagreement (NN) to select 10-20 new candidate structures for which ab initio calculations are performed. e. Add new data, retrain. Iterate until energy/force errors converge.

- DFT Calculation Parameters (VASP example):

- Functional: SCAN or PBEsol (for improved phase stability).

- Plane-wave cutoff: 350 eV minimum.

- k-point spacing: ≤ 0.25 Ã…â»Â¹.

- Include van der Waals correction (D3-BJ).

- Data Formatting: Convert all structures, energies, and forces to standardized format (e.g., ASE database, extended XYZ).

Protocol 2.2: Training a Neural Network Potential (NequIP Framework)

Objective: Train a high-performance, equivariant NN potential.

- Installation:

pip install nequip - Configuration: Create a YAML file (

config.yaml):

- Execution: Run

nequip-train config.yaml. - Validation: Monitor validation loss. Use

nequip-deployto export the model to a.pthfile for LAMMPS/PyTorch.

Protocol 2.3: Training a Gaussian Process Potential (QUIP/GAP Framework)

Objective: Train a data-efficient GP potential with quantified uncertainty.

- Environment: Install QUIP and GAP codes.

- Descriptor Calculation: Generate Smooth Overlap of Atomic Positions (SOAP) descriptors for the training set.

GAP Fitting: Use the

gap_fitcommand.Output: This produces a

gap.xmlfile for use in LAMMPS/QUIP.

Mandatory Visualizations

MLIP Development & Active Learning Workflow

NN vs GP Architecture Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Software and Computational Tools for MLIP Development in PCM Research

| Tool/Reagent | Category | Primary Function | Key Considerations for PCM |

|---|---|---|---|

| VASP | Ab Initio Calculator | Generate training data (energy, forces, stresses). | Use meta-GGA (SCAN) for accurate GeSbTe phase energies. |

| LAMMPS | MD Engine | Perform large-scale simulations with fitted MLIPs. | Supports both NN (libtorch) and GP (QUIP) interfaces. |

| ASE | Atomic Simulation Environment | Python toolkit for structure manipulation, workflow. | Central hub for converting between codes and formats. |

| NequIP / Allegro | NN Potential Framework | Train E(3)-equivariant NN potentials. | State-of-the-art accuracy; requires PyTorch expertise. |

| QUIP & GAP | GP Potential Framework | Train Gaussian Approximation Potentials. | Excellent for small-data onset and uncertainty. |

| SNAFU / DEEPMD | Training/Active Learning | Automate dataset generation and model iteration. | Critical for building robust datasets efficiently. |

| SOAP / ACE | Descriptor | Convert atomic environments into mathematical vectors. | The "language" both NN and GP models understand. |

| High-Performance Computing (HPC) Cluster | Infrastructure | Provide CPU/GPU resources for DFT and ML training. | GPU acceleration crucial for training large NNs. |

| cis-1,2-Difluorocyclopropane | cis-1,2-Difluorocyclopropane, CAS:57137-41-4, MF:C3H4F2, MW:78.06 g/mol | Chemical Reagent | Bench Chemicals |

| 1,4-Dimethylbicyclo[2.2.2]octane | 1,4-Dimethylbicyclo[2.2.2]octane | Bench Chemicals |

Application Notes

The integration of Machine-Learned Interatomic Potential (MLIP)-optimized Phase Change Memory (PCM) materials into biomedical devices presents a transformative opportunity for intelligent, data-dense implants and bio-sensors. The core material triad of Biocompatibility, Switching Speed, and Data Retention defines their applicability. This document provides application notes and protocols framed within ongoing MLIP-PCM research for biomedical engineering.

- Biocompatibility: The non-negotiable prerequisite. Materials must not elicit cytotoxic, inflammatory, or thrombogenic responses. For implants, long-term stability without degradation or ion leaching is critical. MLIP-driven discovery focuses on screening alloys of Ge, Sb, Te (GST), and novel dopants (e.g., N, C, Se) for enhanced chemical inertness in physiological environments.

- Switching Speed: Determines the operational bandwidth of a device. Fast amorphization (RESET) and crystallization (SET) speeds (nanosecond to microsecond scale) are vital for real-time biosignal processing (e.g., neural spike recording) or rapid drug release triggering.

- Data Retention: The ability to maintain a programmed resistive state at body temperature (~37°C). High retention, typically quantified by archival lifetime (time for resistance to decay at a constant temperature), ensures the stability of stored therapeutic protocols or calibration data over the device's lifetime.

The interplay of these properties is a trade-off: enhancing retention often requires materials with higher crystallization temperature, which can slow switching speed. MLIP models enable precise atomic-level tuning to navigate this trade-off for specific biomedical use-cases (e.g., a chronic implant prioritizes retention and biocompatibility, while a lab-on-a-chip sensor may prioritize speed).

Quantitative Data Summary

Table 1: Key Properties of PCM Alloys for Biomedical Evaluation

| Material System | Typical Composition | Crystallization Temperature (Tx) @ 37°C Stability | Switching Speed (SET/RESET) | Biocompatibility Notes (In-Vitro) | Key Biomedical Application Target |

|---|---|---|---|---|---|

| GST-225 | Ge2Sb2Te5 | ~150°C (High Retention) | ~50-100 ns | Moderate; Te leaching concerns in long-term fluid contact. | Non-implantable bio-sensors, lab-on-chip memory. |

| N-Doped GST | (Ge2Sb2Te5)1-xNx | Increased by 20-40°C | Slightly slowed vs. GST | Improved; N-doping reduces Te diffusion and enhances stability. | Chronic neural implants, programmable drug elution substrates. |

| Sb2Te3 / Ge-rich | Ge-rich Sb2Te3 | Tunable, ~100-200°C | Ultra-fast (<10 ns) | Similar to GST; requires encapsulation. | High-speed diagnostic processors. |

| Scanning MLIP Candidates | e.g., Sb-Se, Ge-Sb-S | MLIP-Predicted >200°C | MLIP-Optimized | In-silico toxicity screening prior to synthesis. | Next-generation fully bio-inert memory elements. |

Table 2: Standard In-Vitro Biocompatibility Assay Benchmarks (ISO 10993-5)

| Assay | Purpose | Quantitative Readout | Pass/Fail Threshold (for PCM materials) | Protocol Reference |

|---|---|---|---|---|

| MTT/XTT | Cell Viability & Metabolism | Optical Density (OD) @ 450-500nm | >70% viability vs. control | Protocol 1 below |

| Direct Contact | Cytotoxicity & Morphology | Zone of lysis, cell rounding score (0-4) | Score ≤ 2; No measurable zone | Protocol 1 below |

| Hemolysis Test | Blood compatibility | % Hemoglobin release | <5% hemolysis (non-hemolytic) | Protocol 2 below |

| Ion Release (ICP-MS) | Long-term material stability | [Ion] in ppb in simulated body fluid | [Te] < 10 ppb; [Sb] < 25 ppb | - |

Experimental Protocols

Protocol 1: In-Vitro Cytotoxicity and Viability Assay (MTT/Direct Contact) Objective: To evaluate the cytotoxic response of PCM material thin films in contact with mammalian fibroblast cells (L929 or NIH/3T3). Materials: PCM thin-film wafer (sterilized by UV/ethanol), cell culture, 24-well plate, Dulbecco’s Modified Eagle Medium (DMEM), MTT reagent, DMSO, incubator. Procedure: 1. Sample Preparation: Dice PCM wafer into 1x1 cm squares. Sterilize via sequential 70% ethanol wash and UV exposure for 30 min per side. 2. Cell Seeding: Seed L929 fibroblasts in a 24-well plate at 5x10^4 cells/well in 1 mL complete DMEM. Incubate for 24h (37°C, 5% CO2) to form a sub-confluent monolayer. 3. Direct Contact Test: Gently place one sterile PCM sample atop the cell monolayer in test wells. Include a negative control (high-density polyethylene) and a positive control (tin-stabilized PVC). Add fresh medium to cover the sample. 4. Incubation: Incubate the plate for 24-48 hours. 5. MTT Assay: Remove medium and samples. Add 500 μL of fresh medium containing 0.5 mg/mL MTT reagent to each well. Incubate for 3 hours. 6. Solubilization: Remove MTT solution. Add 500 μL of DMSO to each well to dissolve the formazan crystals. 7. Quantification: Transfer 100 μL from each well to a 96-well plate. Measure absorbance at 570 nm using a microplate reader. Calculate cell viability as: (ODtest / ODnegative control) x 100%. 8. Morphology Assessment: Observe cells under a phase-contrast microscope for rounding, detachment, or lysis. Score cytotoxicity per ISO 10993-5.

Protocol 2: Hemocompatibility Assessment (Static Hemolysis Test) Objective: To determine the hemolytic potential of PCM materials in direct contact with blood. Materials: PCM material powder or polished disc, anticoagulated whole rabbit blood, normal saline (0.9% NaCl), deionized water, centrifuge, spectrophotometer. Procedure: 1. Sample Preparation: Extract material leachate by immersing PCM sample in normal saline (3 cm²/mL surface area to volume ratio) at 37°C for 72h. Use powder (<100 µm particle size) for high-surface-area testing. 2. Blood Preparation: Dilute fresh anticoagulated rabbit blood with normal saline (4:5 v/v). 3. Incubation: Add 1 mL of diluted blood to 10 mL of: a) Test sample extract, b) Negative control (normal saline), c) Positive control (deionized water). Incubate at 37°C for 3 hours with gentle mixing. 4. Centrifugation: Centrifuge all tubes at 750 x g for 10 minutes. 5. Measurement: Carefully pipette the supernatant. Measure its absorbance at 545 nm (peak for hemoglobin). 6. Calculation: Calculate percent hemolysis: % Hemolysis = [(ODtest - ODnegative) / (ODpositive - ODnegative)] x 100%.

Visualization

MLIP-PCM Biomedical Development Workflow

Property Trade-Offs & MLIP Optimization

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for PCM Biomedical Characterization

| Item | Function/Benefit | Example/Note |

|---|---|---|

| PCM Target (N-doped GST) | Source for thin-film deposition via sputtering. Enables precise stoichiometric control. | Kurt J. Lesker, 2-inch diameter, 99.999% purity. |

| Simulated Body Fluid (SBF) | Ionic solution mimicking human blood plasma for in-vitro corrosion & ion release studies. | pH 7.4 at 37°C, per Kokubo recipe. |

| L929 Fibroblast Cell Line | Standardized model for cytotoxicity testing per ISO 10993-5. | ATCC CCL-1, readily available. |

| Hemolysis Assay Kit | Provides standardized reagents and protocol for accurate % hemolysis calculation. | BioVision K782-100, includes lysis buffer. |

| MTT Cell Proliferation Kit | Ready-to-use solution for accurate, high-throughput viability screening. | Roche 11465007001. |

| ICP-MS Calibration Standard | For quantifying trace metal ion (Sb, Te, Ge) release from materials. | Multi-element standard in dilute HNO3. |

| Parylene-C Deposition System | For conformal, biocompatible encapsulation of fabricated PCM devices. | Protects against body fluid ingress. |

A Practical Guide: Implementing MLIPs for PCM Discovery and Biomedical Device Design

This protocol details the comprehensive workflow for generating a robust Machine Learning Interatomic Potential (MLIP) targeted at phase change memory (PCM) materials, such as Ge-Sb-Te (GST) alloys. The broader thesis context focuses on enabling high-fidelity, large-scale molecular dynamics simulations to study crystallization kinetics, amorphous phase stability, and defect dynamics in PCMs—properties critical to device performance, endurance, and switching speed. The blueprint bridges first-principles accuracy with computational efficiency required for device-scale modeling.

Application Notes & Protocols

Protocol:Ab-InitioDataset Generation for PCM Materials

Objective: To create a diverse, representative, and high-quality dataset of atomic configurations and their corresponding energies, forces, and stresses from Density Functional Theory (DFT) calculations.

Detailed Methodology:

Initial Structure Curation:

- Source crystalline prototypes (e.g., rocksalt GeTe, Sb₂Te₃) from materials databases (ICSD).

- Generate amorphous structures via melt-quench using a preliminary classical potential in an MD simulation.

- Create slabs, surfaces (e.g., (100), (111) facets), and vacancy-defected cells to include critical non-bulk environments.

Active Learning-Driven Sampling (via VASP + LAMMPS):

- Step A (Seed Calculation): Perform static DFT calculations on ~100 initial configurations.

- Step B (MLIP Drafting): Train a preliminary MLIP (e.g., MACE, NequIP) on the seed data.

- Step C (Exploratory MD): Run high-temperature (e.g., 1500 K), long-duration MD simulations using the draft MLIP to probe unseen regions of configuration space.

- Step D (Uncertainty Quantification): Use the committee model (ensemble) or latent distance metrics (e.g., in DPG) to identify configurations with high predictive uncertainty.

- Step E (Iterative Augmentation): Select the top N most uncertain configurations, compute their accurate DFT properties, and add them to the training set.

- Repeat Steps B-E for 5-10 cycles until uncertainty metrics plateau across validation sets.

DFT Calculation Parameters (PAW-PBE):

- Software: VASP (version 6.4+).

- Cut-off Energy: 400 eV for GST alloys.

- k-point spacing: 0.25 Ã…â»Â¹ (Γ-centered Monkhorst-Pack grid).

- Convergence: SCF tolerance of 10â»â¶ eV; ionic relaxation until forces < 0.01 eV/Ã….

- Stress Tensor: Calculate for all configurations to train MLIP on virial stress.

Quantitative Dataset Summary: Table 1: Representative DFT Dataset Composition for a Geâ‚‚Sbâ‚‚Teâ‚… Model System

| Configuration Type | Number of Structures | Avg. Atoms/Structure | Total Energy (DFT) Range (eV/atom) | Primary Purpose |

|---|---|---|---|---|

| Bulk Crystalline (Varied Cell) | 350 | 90 | -4.8 to -4.5 | Baseline bulk properties |

| Amorphous (Melt-Quenched) | 220 | 108 | -4.6 to -4.3 | Glassy phase representation |

| Defected (Vacancies, Surfaces) | 180 | Variable | -4.9 to -4.2 | Defect formation energies |

| High-T MD Snapshots (Active Learning) | 750 | 64 | -4.7 to -4.0 | Sampling of metastable states |

| Total Dataset | ~1500 | ~80 (avg.) | -4.9 to -4.0 | Comprehensive Training |

Protocol: MLIP Model Training & Validation

Objective: To transform the ab-initio dataset into a transferable, accurate, and computationally efficient interatomic potential.

Detailed Methodology:

Data Partitioning:

- Split the full dataset: 70% Training, 15% Validation, 15% Test. Ensure no time-correlated snapshots from the same MD trajectory leak across splits.

Model Architecture & Training (Example using MACE):

- Software: MACE (MPNN with ACE basis) or NequIP (E(3)-equivariant GNN).

- Hyperparameters:

- Radial cutoff: 5.0 Ã….

- Max spherical harmonic degree (l_max): 3.

- Hidden feature dimensions: 128.

- Number of interaction layers: 3.

- Loss Function: Weighted sum of energy (MSE), force (MSE), and stress (MSE) errors.

Loss = w_E * L_E + w_F * L_F + w_S * L_S(typical starting weights: 1, 100, 0.01). - Optimization: Use AdamW optimizer with an initial learning rate of 0.01 and exponential decay scheduling.

Rigorous Validation Metrics:

- Primary Metrics (on Test Set): Report Root Mean Square Error (RMSE) and Mean Absolute Error (MAE) for energy (meV/atom), forces (meV/Ã…), and stresses (GPa).

- Physical Validation: Use the trained MLIP to compute:

- Equation of State (EOS) for crystalline phases vs. DFT.

- Radial Distribution Function (RDF) of amorphous Geâ‚‚Sbâ‚‚Teâ‚… vs. DFT-MD.

- Phonon Density of States (DoS) for the crystalline phase.

Quantitative Performance Summary: Table 2: Typical MLIP Model Performance Benchmarks for GST

| Metric | Target Value (Test Set) | Typical Achieved Performance | Pass/Fail Criteria |

|---|---|---|---|

| Energy RMSE | < 10 meV/atom | 3-8 meV/atom | PASS |

| Force RMSE | < 100 meV/Ã… | 50-80 meV/Ã… | PASS |

| Lattice Constant (GeTe) | DFT: 6.02 Å | MLIP: 6.00 ± 0.03 Å | PASS |

| Amorphous RDF 1st Peak Pos. | DFT: ~2.85 Å | MLIP: 2.83 ± 0.05 Å | PASS |

| Melting Point (GeTe) | ~1000 K | Predicted within ±50 K | PASS |

Mandatory Visualizations

Diagram 1: MLIP Development Workflow for PCM Research

Diagram 2: Active Learning Data Generation Cycle

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools & Materials for MLIP Development

| Item Name | Function/Benefit | Example/Note |

|---|---|---|

| VASP (Vienna Ab-initio Simulation Package) | Industry-standard DFT code for generating reference energies, forces, and stresses. Essential for high-accuracy seed data. | Requires a commercial license. PAW-PBE pseudopotentials recommended. |

| LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator) | MD engine for running exploratory simulations with draft MLIPs and final production runs with the trained model. | Supports many MLIP formats (e.g., ML-IAP). |

| MACE or NequIP Framework | State-of-the-art, equivariant graph neural network architectures for constructing high-accuracy MLIPs. | MACE offers excellent performance; NequIP is highly sample-efficient. |

| ASE (Atomic Simulation Environment) | Python toolkit for manipulating atoms, interfacing between DFT/MD codes, and analyzing results. | Glue code for workflow automation. |

| HPC Cluster with GPU Nodes | Computational infrastructure. GPU acceleration (NVIDIA A100/V100) is critical for training MLIPs and fast MD. | ~4-8 GPUs recommended for training on 1500+ structures. |

| Active Learning Driver (e.g., FLARE, AL4ME) | Automates the uncertainty sampling loop between DFT and draft MLIPs. | Custom Python scripting is often required for specific materials. |

| Phonopy Software | For calculating phonon spectra to validate MLIP dynamical properties against DFT. | Critical for ensuring stability of simulated phases. |

| 2,3,4-Trimethylheptane | 2,3,4-Trimethylheptane, CAS:52896-95-4, MF:C10H22, MW:142.28 g/mol | Chemical Reagent |

| 9,17-Octadecadienal, (Z)- | 9,17-Octadecadienal, (Z)-|CAS 56554-35-9 | 9,17-Octadecadienal, (Z)- is a high-purity reference standard for research. This product is For Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

Active Learning Strategies for Efficient Exploration of PCM Compositional Space

1. Introduction & Thesis Context Within the broader thesis on Machine Learning Interatomic Potential (MLIP) for phase-change memory (PCM) materials application research, the primary bottleneck is the efficient generation of high-fidelity training data for the MLIP. The compositional space of candidate PCMs (e.g., Ge-Sb-Te, Sb-Te, Ge-Sb systems doped with elements like Se, In, Bi) is vast. Active Learning (AL) provides a strategic framework to iteratively and intelligently select the most informative compositions and atomic configurations for Density Functional Theory (DFT) calculation, minimizing computational expense while maximizing MLIP predictive accuracy and reliability for properties like crystallization speed, phase stability, and resistance contrast.

2. Core Active Learning Workflow for PCM Discovery The closed-loop AL cycle integrates four key phases: Initial Data Generation, MLIP Training & Uncertainty Quantification, Query Strategy, and Targeted DFT Validation.

Title: Active Learning Loop for PCM Materials

3. Key Experimental & Computational Protocols

Protocol 3.1: Initial Dataset Construction via Ab-Initio Molecular Dynamics (AIMD)

- Objective: Generate diverse atomic configurations (liquid, amorphous, crystalline phases) for initial MLIP training.

- Method:

- Structure Generation: For a target composition (e.g., Geâ‚‚Sbâ‚‚Teâ‚…), create supercells (e.g., 216 atoms) in crystalline (rock-salt) and randomized amorphous-like structures using atomic substitution and spatial disordering.

- AIMD Simulation: Perform DFT-based MD using VASP or CP2K.

- Temperature: Run short simulations (5-10 ps) across a range (600K, 900K, 1200K) to sample liquid and high-T phases.

- Quenching: Rapidly quench (e.g., 300 K/ps) from the melt to generate amorphous configurations.

- Data Extraction: From AIMD trajectories, extract snapshots at regular intervals (e.g., every 100 fs). For each snapshot, compute the energy, atomic forces, and stress tensors using DFT. This forms the initial labeled dataset

(Atomic Coordinates, {E_i, F_ij, σ_ij}).

Protocol 3.2: MLIP Training & Uncertainty Quantification using Ensemble Method

- Objective: Train a model and estimate its predictive uncertainty on new compositions.

- Method:

- Model Choice: Employ a neural network-based MLIP architecture (e.g., MACE, NequIP) or Gaussian Approximation Potential (GAP).

- Ensemble Training: Train N independent models (N=5-10) on different 80% bootstrapped subsets of the current training data.

- Uncertainty Metric: For a new candidate configuration, the uncertainty (

σ) is defined as the standard deviation of the predicted energies (or per-atom forces) across the ensemble of N models. Highσindicates a region of compositional/configuration space where the MLIP is poorly determined.

Protocol 3.3: Query-by-Committee for Targeted DFT Validation

- Objective: Identify the most promising candidates for expensive DFT validation.

- Method:

- Candidate Pool: Generate a large pool of potential compositions (e.g., via substitution in a GeSbTe base) and configurations (using classical MD or random perturbation).

- MLIP Screening: Use the trained MLIP ensemble to predict formation energy and uncertainty for all candidates.

- Pareto Frontier Selection: Rank candidates based on:

- Exploration: High MLIP uncertainty (

σ). - Exploitation: Predicted favorable property (e.g., low formation energy near known PCMs, high energy gap between phases).

- Exploration: High MLIP uncertainty (

- Selection: Choose 10-20 configurations from the Pareto-optimal frontier for DFT validation (Protocol 3.1, Step 2). Prioritize compositions with high uncertainty and predicted good stability.

4. Data Presentation: Representative AL Cycle Performance

Table 1: Performance Metrics Across Active Learning Cycles for Ge-Sb-Te-Se Systems

| AL Cycle | # of DFT Configurations | MLIP MAE on Hold-out Test Set (meV/atom) | Max. Uncertainty (σ) Sampled (meV/atom) |

New Promising Composition Identified (Predicted ΔH < 0.05 eV/atom) |

|---|---|---|---|---|

| 0 (Initial) | 500 | 12.5 | 85.2 | N/A |

| 1 | 620 | 8.7 | 45.1 | Geâ‚Sbâ‚‚Teâ‚‚Seâ‚ |

| 2 | 725 | 5.2 | 22.3 | Geâ‚Sbâ‚Teâ‚‚Seâ‚‚ |

| 3 | 800 | 3.1 | 10.5 | Geâ‚‚Sbâ‚Teâ‚Seâ‚‚ |

| Convergence | ~800 | < 5.0 | < 15.0 | 3-5 novel candidates |

Table 2: Key Research Reagent Solutions & Computational Tools

| Item Name | Category | Function in PCM AL Research |

|---|---|---|

| VASP/CP2K | Ab-Initio Software | Performs DFT calculations to generate gold-standard energy, force, and stress labels for MLIP training. |

| LAMMPS | MD Simulator | Used for high-throughput sampling of configurations (e.g., melting, quenching) with fitted MLIPs. |

| MACE/NequIP/GAP | MLIP Architecture | Machine learning models that map atomic configurations to quantum-mechanical properties. |

| ASE (Atomic Simulation Environment) | Python Toolkit | Manages workflow, interfaces between DFT, MD, and MLIP codes, and analyzes structures. |

| SAMPLE (or custom) | AL Query Library | Implements uncertainty sampling (e.g., D-optimal, ensemble variance) and diversity selection algorithms. |

| Materials Project Database | Initial Structure Source | Provides known crystalline structures as seeds for doping and AIMD simulations. |

5. Advanced AL Query Strategy Logic

Title: Multi-Filter Query Strategy for PCMs

Application Notes

The discovery and optimization of phase-change materials (PCMs) for memory applications require precise prediction of key performance metrics: crystallization kinetics (data write speed), melting point (thermal stability), and electronic band gap (electrical contrast). This protocol details an integrated computational and experimental workflow, framed within a broader thesis on Machine Learning Interatomic Potential (MLIP)-driven PCM research, to accelerate the development of novel chalcogenide alloys (e.g., Ge-Sb-Te systems).

Table 1: Benchmark Performance of ML Models for PCM Property Prediction (2023-2024)

| Model Architecture | Target Property | Dataset Size | MAE (Primary Metric) | Key Reference/Platform |

|---|---|---|---|---|

| Graph Neural Network (MEGNet) | Formation Energy & Band Gap | ~60k materials (MP) | Band Gap: ~0.3 eV | MatDeepLearn, MatterNet |

| Random Forest (RF) | Melting Point (Tm) | ~10k inorganic compounds | Tm: ~100 K | Citrine Informatics, AFLOW |

| Gradient Boosting (XGBoost) | Crystallization Temperature (Tx) | ~1.5k PCM compositions | Tx: ~15 K | J. Phys. Chem. C (2024) |

| Neural Network Potentials (e.g., NequIP) | Atomic Forces/Energy (for kinetics) | ~100k DFT trajectories | Energy: < 10 meV/atom | arXiv:2401.15247 (2024) |

Table 2: Exemplary Predicted vs. Experimental Values for GST-225

| Property | ML Prediction | Experimental Range | Critical for PCM Function |

|---|---|---|---|

| Crystallization Temp. (Tx) | 433 K | 420 - 450 K | Determines write speed and data retention. |

| Melting Point (Tm) | 893 K | 883 - 903 K | Indicates thermal stability of amorphous phase. |

| Band Gap (Eg) - Crystalline | 0.5 eV | 0.5 - 0.7 eV | Defines electrical contrast between states. |

| Band Gap (Eg) - Amorphous | 0.7 eV | 0.7 - 0.9 eV | Critical for readout signal. |

Experimental Protocols for Validation

Protocol A: Ultrafast Calorimetry for Crystallization Kinetics

- Objective: Measure crystallization kinetics (activation energy, rate constant) of thin-film PCMs to validate ML-predicted stability.

- Materials: Thin-film PCM library (e.g., Geâ‚‚Sbâ‚‚Teâ‚…, doped variants) on SiOâ‚‚/Si substrates, Flash DSC (Differential Scanning Calorimetry) or nanocalorimetry system.

- Procedure:

- Sample Preparation: Deposit 20-100 nm PCM films via magnetron sputtering. Pattern into isolated micro-pads for nanocalorimetry.

- Ramp Experiment: Subject sample to controlled linear heating ramp (e.g., 10â´ K/s) while measuring heat flow. Identify crystallization peak temperature (Tx).

- Isothermal Experiment: Rapidly heat sample to a temperature just below Tx and hold. Monitor heat flow over time to extract crystallization rate.

- Analysis: Apply Johnson-Mehl-Avrami-Kolmogorov (JMAK) model to isothermal data to extract activation energy for crystallization (Ea). Compare Ea and Tx with ML predictions.

Protocol B: Spectroscopic Ellipsometry for Band Gap Determination

- Objective: Determine the optical band gap of amorphous and crystalline PCMs.

- Materials: PCM thin films (as-deposited and laser-crystallized), spectroscopic ellipsometer (UV-Vis-NIR range).

- Procedure:

- Measurement: Acquire ellipsometry angles (Ψ, Δ) over spectral range 0.5 - 6.5 eV.

- Model Fitting: Construct a Tauc-Lorentz oscillator model to fit the measured complex dielectric function.

- Band Gap Extraction: Plot (αhν)^(1/2) vs. hν (for indirect gap, typical for GST). Extrapolate the linear region to the x-intercept to determine the Tauc optical band gap.

- Validation: Compare measured band gaps for both phases against ML-predicted electronic band structures.

Visualization of Workflows

Diagram 1: MLIP-Driven PCM Discovery Workflow

Diagram 2: Experimental Validation Protocol Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PCM Synthesis and Characterization

| Item | Function in Research | Example Product/Specification |

|---|---|---|

| Chalcogenide Sputtering Targets | Source material for depositing Ge-Sb-Te alloy films. High purity (>99.999%) is critical. | Geâ‚‚Sbâ‚‚Teâ‚…, AgInSbTe quaternary targets, 3-inch diameter. |

| Ultra-Fast DSC Chip Sensors | Enable measurement of crystallization kinetics at heating rates >1000 K/s, mimicking device operation. | Nanocalorimetry sensor chips (e.g., Xensor XEN-39422). |

| Phase-Change Material Database | Curated dataset for ML training, containing compositions, structures, and properties. | PCMGenome, NIMS-PCM, or custom SQL database. |

| MLIP Training Software | Framework to create machine-learned potentials from DFT data for large-scale MD simulations. | NequIP, MACE, DeepMD-kit. |

| High-Throughput DFT Suite | Automates quantum-mechanical calculation of formation energy and band structure for thousands of candidates. | AFLOW, Phonopy, VASP with pymatgen scripts. |

| In-situ TEM Heating Holder | Allows direct observation of crystallization dynamics at atomic scale under controlled temperature. | MEMS-based heating chip holder (up to 1200°C). |

| 3,5-Dimethylcyclohexene | 3,5-Dimethylcyclohexene|C8H14 | 3,5-Dimethylcyclohexene (C8H14) is a high-purity cyclohexene derivative for research applications. This product is for laboratory research use only (RUO) and not for human use. |

| 2-Chloro-3-methylpent-1-ene | 2-Chloro-3-methylpent-1-ene|C6H11Cl|CAS 51302-91-1 | 2-Chloro-3-methylpent-1-ene (C6H11Cl) is a chemical for research use only (RUO). Explore its applications in organic synthesis and as a reference standard. Not for human consumption. |

Within the broader thesis on Machine Learning Interatomic Potential (MLIP) for phase-change memory (PCM) materials application research, a critical challenge is the inherent toxicity of mainstream GST (Ge-Sb-Te) alloys. These materials, while excellent for data storage, pose significant risks for emerging biomedical applications such as implantable neuromorphic devices or controlled drug release systems. This document outlines application notes and protocols for screening novel, biocompatible PCM alloys with reduced toxicity, targeting the replacement of Ge, Sb, and/or Te with less harmful elements while maintaining requisite phase-change properties.

Table 1: Comparative Toxicity and Properties of Standard GST Elements vs. Candidate Substitutes

| Element (Role) | LD50 (Oral Rat, mg/kg) | Key Toxicity Concerns | Biocompatibility Index (Qualitative) | Common PCM Phase |

|---|---|---|---|---|

| Germanium | 1,500 | Kidney damage, neurotoxicity | Low | Crystalline/Amorphous |

| Antimony | 3,000 | Carcinogen, cardio/respiratory toxin | Very Low | Crystalline |

| Tellurium | 83 | Garlic odor, teratogen, hemolytic agent | Very Low | Crystalline/Amorphous |

| Silicon (Ge substitute) | >3,160 | Low systemic toxicity, bio-inert | High | Amorphous (SiO2) |

| Bismuth (Sb substitute) | 5,000 | Low toxicity, radio-opaque | Moderate-High | Crystalline |

| Sulfur/Selenium (Te substitute) | S: 8,430; Se: 6,700 | Essential trace elements in controlled doses | Moderate (dose-dependent) | Chalcogenide backbone |

Table 2: Target Properties for Biocompatible PCM Candidates

| Property | GST-225 Benchmark | Biocompatible Target | Measurement Method |

|---|---|---|---|

| Melting Point (°C) | ~600 | 400-550 | DSC |

| Resistivity Contrast (Ω·cm) | 10^3-10^4 | ≥10^3 | 4-point probe |

| Crystallization Temp. (°C) | ~150 | 100-200 (tunable) | In-situ TEM/DSC |

| Endurance Cycles | >10^8 | >10^6 | Electrical testing |

| Cytotoxicity (Cell Viability %) | <50% (reported) | >80% (ISO 10993-5) | MTT/LDH assay |

Experimental Protocols

Protocol 3.1: High-Throughput Combinatorial Sputtering for Alloy Library Creation

Objective: To deposit thin-film libraries of candidate alloys (e.g., Si-Sb-Te, Ge-Bi-Se, Si-Bi-S) with compositional gradients. Materials: Multi-target RF/DC magnetron sputtering system; 4-inch Si/SiO2 wafers; high-purity targets (Si, Ge, Sb, Bi, Te, Se, S); mass flow controllers (Ar gas). Procedure:

- Substrate Preparation: Clean wafers with sequential acetone, isopropanol, and DI water rinses. Dry with N2.

- System Pump-down: Achieve base pressure ≤ 5×10^-7 Torr.

- Co-deposition Setup: Position substrate on a rotating stage between multiple targets. Use shadow masks to create lateral composition spreads.

- Deposition Parameters: Set Ar pressure to 3 mTorr. Adjust individual target powers (20-150W) to achieve desired composition range. Deposit for 60 min to obtain ~100 nm films.

- Post-deposition: Anneal library in vacuum (250°C, 10 min) to relieve stress.

- Characterization: Use EDX mapping across wafer to create composition map.

Protocol 3.2: Cytotoxicity Screening via Direct Contact Assay (ISO 10993-5)

Objective: Evaluate in vitro cytotoxicity of novel alloy films. Materials: L929 mouse fibroblast cells; DMEM + 10% FBS; 24-well plates; MTT reagent (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide); DMSO; alloy samples (1×1 cm2, sterilized by UV). Procedure:

- Sample Preparation: Sterilize alloy films under UV for 30 min per side. Place one sample per well in 24-well plate.

- Cell Seeding: Trypsinize L929 cells, count, and seed at 1×10^4 cells/well in 1 mL medium. Incubate at 37°C, 5% CO2 for 24h to allow attachment.

- Direct Contact: Carefully place sterilized film onto cell monolayer. Incubate for further 24h.

- MTT Assay: Add 100 μL MTT solution (5 mg/mL in PBS) to each well. Incubate 4h. Carefully remove medium and film. Add 500 μL DMSO to dissolve formazan crystals.

- Analysis: Measure absorbance at 570 nm with 650 nm reference. Calculate cell viability relative to control (wells without film). Viability >80% is considered non-cytotoxic.

Protocol 3.3: Phase-Change Electrical Characterization

Objective: Measure resistivity contrast and switching endurance of candidate materials. Materials: Probe station with hot chuck; semiconductor analyzer (Keysight B1500A); T-type thermocouple; pre-patterned test devices (50 nm thick film between TiN electrodes, 100 nm via). Procedure:

- Temperature-dependent Resistance (R-T): Place device on hot chuck. Ramp temperature from 25°C to 400°C at 10°C/min in N2 atmosphere. Measure resistance continuously with 0.1V bias.

- Crystallization Kinetics: Hold at specific temperatures (e.g., 150, 175, 200°C) and measure resistance vs. time.

- Switching Test: Apply voltage pulses (10-100 ns width, 1-5V amplitude) using pulse generator. Monitor current to detect SET (to crystalline) and RESET (to amorphous) transitions.

- Endurance Testing: Apply repetitive SET/RESET pulse trains (e.g., 10^6 cycles) and monitor resistance window degradation.

Visualization: Experimental and Analytical Workflows

Title: Biocompatible PCM Screening Workflow

Title: GST Toxicity Signaling Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biocompatible PCM Research

| Item | Function & Rationale | Example Vendor/Product |

|---|---|---|

| Combinatorial Sputtering System | Deposits continuous composition-spread libraries for high-throughput screening. Essential for exploring ternary/quaternary phase diagrams. | Korvus Technology HEX Series |

| CytoSMART Exact FL | Live-cell imaging microscope for non-invasive, long-term monitoring of cell viability and morphology in direct contact with alloy samples. | CytoSMART |

| MTT Cell Proliferation Kit | Colorimetric assay to quantify metabolic activity as a proxy for cell viability post-exposure to alloy extracts or direct contact. | Abcam (ab211091) |

| Multimode AFM with NanoTA | Measures nanoscale thermal properties (phase transition temperature, thermal conductivity) critical for PCM performance. | Bruker Dimension Icon with NanoTA module |

| In-situ TEM Heating Holder | Enables direct visualization of crystallization dynamics and phase evolution in thin films under controlled temperature. | Protochips Aduro series |

| Phase-Change Material Characterization Software | Analyzes R-T, I-V, and endurance data, extracting key parameters like activation energy for crystallization. | Keysight PathWave Materials Science |

| MLIP Training Suite (e.g., DeePMD-kit) | Software for developing machine-learned interatomic potentials from DFT data, enabling rapid prediction of new alloy properties. | DeepModeling DeePMD-kit |

| Sterile Alloy Discs (6 mm) | Pre-cut, sterilized sample discs for direct insertion into well plates for cytotoxicity assays, ensuring consistency. | Custom order from vendor (e.g., Goodfellow). |

| Methyl phenyl oxalate | Methyl Phenyl Oxalate|C9H8O4|CAS 38250-12-3 | Methyl Phenyl Oxalate is a key intermediate for synthesizing diphenyl carbonate. This product is For Research Use Only. Not for human or veterinary use. |

| 2,4-Dimethyl-3,5-heptanedione | 2,4-Dimethyl-3,5-heptanedione, CAS:37484-68-7, MF:C9H16O2, MW:156.22 g/mol | Chemical Reagent |

Application Notes

Within the broader thesis on Machine Learning Interatomic Potential (MLIP) applications for Phase Change Memory (PCM) materials, this document details their application in designing novel PCM alloys for ultra-fast, high-density biomolecular data storage. The core challenge is identifying materials that enable rapid, reversible switching between amorphous and crystalline states to encode binary data (0/1), with exceptional endurance and stability at the scale of individual biomolecules (e.g., DNA, peptides).

1.1 Rationale & Scientific Context Traditional PCM materials like Geâ‚‚Sbâ‚‚Teâ‚… (GST-225) face limitations in write/erase speed, power consumption, and thermal stability at sub-nanometer scales relevant for interfacing with biomolecular substrates. MLIPs, trained on high-fidelity quantum mechanics data, enable nanosecond-scale molecular dynamics (MD) simulations with near-DFT accuracy. This allows for the in silico screening of millions of ternary/quaternary chalcogenide compositions to optimize key properties for biomolecular integration: ultra-low switching energy, reduced atomic migration, and tailored crystallization kinetics compatible with biomolecular preservation.

1.2 Key Performance Targets (Quantitative) The following table summarizes the target properties for next-generation PCMs in biomolecular data storage, compared to the traditional baseline.

Table 1: Target PCM Properties for Biomolecular Data Storage

| Property | Traditional GST-225 (Baseline) | MLIP-Optimized Target | Significance for Biomolecular Storage |

|---|---|---|---|

| Crystallization Speed | ~50-100 ns | < 5 ns | Enables writing data on timescales relevant to biomolecular interactions. |

| Reset/Amorphization Energy | ~10-100 pJ/bit | < 1 pJ/bit | Minimizes thermal load to prevent denaturation of adjacent biomolecules. |

| Crystallization Temperature (Tₓ) | ~150-180 °C | > 250 °C | Ensures data retention (thermal stability) under ambient and processing conditions. |

| Resistance Contrast (Râ‚ₘᵣₚₕ/Rᵣᵧₛₜ) | 10³ - 10âµ | > 10âµ | Enables clear readout signals with minimal error when scaled to molecular dimensions. |

| Endurance Cycles | 10⸠- 10¹² | > 10¹² | Supports repeated writing/erasing for dynamic biological data storage systems. |

| Required Switching Volume | ~(10 nm)³ | Approaching (3 nm)³ | Allows data encoding on the scale of individual protein complexes or DNA segments. |

1.3 MLIP-Driven Discovery Workflow The discovery pipeline involves a closed-loop feedback between MLIP-based simulation and experimental synthesis/validation, as detailed in the protocol section.

Experimental Protocols

2.1 Protocol: High-Throughput In Silico Screening of PCM Compositions Using MLIP-MD

Objective: To computationally identify promising (Ge,Sb,Bi,In)-(Se,Te) compositions meeting the targets in Table 1.

Materials & Software:

- MLIP Model (e.g., MACE, NequIP, Allegro) pre-trained on a diverse dataset of chalcogenide materials (energies, forces, stresses from DFT).

- Atomic structure files for candidate compositions (e.g., from Materials Project).

- High-Performance Computing (HPC) cluster.

- LAMMPS or ASE software with MLIP interface.

Procedure:

- Composition Space Definition: Define the search space (e.g., GeₓSbᵧBi₂Te₃, where x+y+z=2).

- Structure Generation: For each composition, generate 10-20 randomized initial atomic configurations in a 3x3x3 supercell (~500 atoms).

- Equilibration MD: For each configuration, run NPT-MD at 500 K for 100 ps using the MLIP to equilibrate density.

- Glass Formation Simulation: Quench the equilibrated melt from 500 K to 300 K at a rate of 5 K/ps. A successful glass (amorphous phase) formation is confirmed by radial distribution function (RDF) analysis.

- Crystallization Kinetics: Heat the amorphous model from 300 K to a temperature just above predicted Tâ‚“ (from previous MD) and hold for 10-20 ns. Monitor the potential energy and RDF for abrupt drops indicating crystallization. The time constant (Ï„) is extracted via Avrami analysis.

- Property Calculation:

- Tâ‚“: Using the Kissinger method on crystallization times from step 5 at multiple temperatures.

- Band Gap: Perform DFT single-point calculations on MLIP-relaxed amorphous and crystalline structures.

- Resistance Contrast: Estimate using the inverse relationship with electrical conductivity approximated from the band gap and carrier mobility models.

- Down-Selection: Rank compositions based on simultaneous optimization of high Tâ‚“, low Ï„, and high band gap contrast.

2.2 Protocol: Experimental Validation of MLIP-Predicted PCM Thin Films

Objective: To synthesize and characterize the top candidate material (e.g., GeSbBiTe) identified from Protocol 2.1.

Materials:

- Sputtering target with MLIP-predicted stoichiometry.

- Si/SiOâ‚‚ wafers with pre-fabricated 50 nm TiN bottom electrodes.

- DC/RF magnetron sputtering system.

- In-situ heating stage in a transmission electron microscope (TEM).

- Picosecond laser pump-probe system or electrical pulse tester.

- Semiconductor parameter analyzer.

Procedure:

- Thin Film Deposition: Deposit a 20 nm amorphous PCM film on the substrate at room temperature using sputtering (Ar pressure: 3 mTorr, power: 30 W DC).

- Structural & Chemical Verification: Perform XRD (confirm amorphous) and energy-dispersive X-ray spectroscopy (EDS) to verify composition.

- In-situ TEM Crystallization: Pattern the film into nanoscale devices (≤ 50 nm). Using a MEMS heating holder, record TEM videos while ramping temperature at 10 K/min. Directly observe nucleation and growth, measuring crystallization front velocity. Compare to MLIP-MD simulated nucleation barriers.

- Electrical Switching Characterization:

- Using a pulse generator, apply SET pulses (amplitude: 0.5-2.0 V, width: 5-100 ns) to crystallize the device.

- Apply RESET pulses (short, high amplitude, e.g., 3 V, 1 ns) to re-amorphize it.

- Measure I-V curves and resistance states after each pulse to determine switching energy, resistance contrast, and endurance.

Table 2: Key Research Reagent Solutions & Materials

| Item | Function/Description | Key Consideration for Biomolecular Integration |

|---|---|---|

| Quaternary Chalcogenide Sputtering Target (e.g., Geâ‚â‚…Sbâ‚…Bi₈Te₇₂) | Source material for depositing the MLIP-designed PCM thin film. | Precise stoichiometry is critical for achieving predicted properties. |

| Functionalized Si/SiOâ‚‚ Substrate | Support for PCM device fabrication. Surface may be pre-patterned with TiN electrodes and/or silane linkers. | Surface chemistry must be compatible with subsequent biomolecular attachment (e.g., DNA, enzymes). |

| Biomolecular "Capping" Layer (e.g., 5 nm Al₂O₃) | Atomic layer deposited barrier layer. | Protects PCM from biochemical environment and vice-versa, while allowing thermal coupling. |

| Picosecond Laser Pulse System | Provides ultra-fast (ps-ns) optical excitation to simulate the RESET amorphization process. | Used to characterize the ultimate speed limit of the material with minimal thermal crosstalk. |

| In-situ TEM Heating Holder | Allows real-time observation of phase transitions at nanoscale. | Validates MLIP-MD predictions of nucleation sites and growth mechanisms crucial for miniaturization. |

Mandatory Visualizations

Title: MLIP-Driven Closed-Loop PCM Discovery Workflow

Title: Data Encoding Principle in PCM-Biomolecule Hybrid System

Overcoming Hurdles: Mitigating MLIP Limitations and Enhancing Model Reliability for PCM

Within the broader thesis on Machine Learning Interatomic Potential (MLIP) application research for phase-change memory (PCM) materials, a central challenge is the Out-of-Distribution (OOD) problem. PCMs like Ge-Sb-Te (GST) alloys undergo rapid, reversible phase transitions between amorphous and crystalline states. MLIPs, trained on known structural phases, often fail or become unreliable when simulating unknown metastable phases, nucleation events, or liquid-quench processes not represented in the training set. This application note details protocols to diagnose, mitigate, and ensure robust predictions for these unknown phases, which is critical for the ab initio design of next-generation PCM devices.

The OOD problem manifests as a breakdown in the MLIP's extrapolative power. Key metrics for diagnosis include uncertainty quantification (UQ) scores and divergence in predicted physical properties.

Table 1: Quantitative Indicators of OOD Behavior in MLIPs for GST

| Metric | In-Distribution Value (Crystalline GeTe) | OOD Value (Amorphous GST at High T) | Detection Threshold | Measurement Technique |

|---|---|---|---|---|

| Model Uncertainty (Epistemic) | ~0.05 eV/atom | >0.5 eV/atom | >0.2 eV/atom | Ensemble variance / Dropout variance |

| Force RMSE (vs. DFT) | <0.03 eV/Ã… | >0.15 eV/Ã… | >0.1 eV/Ã… | Single-point DFT validation |

| Predicted Density | 6.14 g/cm³ | 5.62 g/cm³ | ±5% from expected | MD simulation (NPT ensemble) |

| Radial Distribution Function (RDF) Peak Sharpness | Sharp, defined peaks | Broad, diffuse first peak | Qualitative shift | Analysis of MD trajectory |

Experimental & Computational Protocols

Protocol 3.1: Active Learning Loop for OOD Detection and Mitigation

This protocol integrates uncertainty-driven data generation to iteratively improve MLIP robustness.

- Initial Model Training: Train an ensemble of 5 neural network potentials (e.g., using

MACEorNequIP) on a seed dataset containing DFT-relaxed structures of crystalline phases (e.g., rock-salt GeTe, hexagonal GST) and a small set of liquid snapshots. - OOD Candidate Sampling: Perform a long-time-scale MD simulation (e.g., 1 ns) of the quenching process from the melt (e.g., 3000 K to 300 K at 10 K/ps).

- Uncertainty Quantification: For every 100th frame in the quench trajectory, compute the predictive uncertainty using the ensemble variance in per-atom energy.

- Structure Selection: Flag all configurations where the mean epistemic uncertainty exceeds the 0.2 eV/atom threshold (see Table 1).

- DFT Validation & Labeling: Perform single-point DFT calculations (using VASP/Quantum ESPRESSO) on the top 50 highest-uncertainty flagged structures to obtain accurate energies and forces.

- Dataset Augmentation: Add these newly labeled DFT structures to the training dataset.

- Model Retraining: Retrain the MLIP ensemble on the augmented dataset. Iterate steps 2-7 until the uncertainty during quench simulations falls below the detection threshold across the entire temperature range.

Protocol 3.2:Ab InitioValidation of Predicted Unknown Phases

This protocol validates the physical realism of a novel phase predicted by an MLIP during an OOD simulation.

- Structure Harvesting: From an MLIP MD simulation, identify a stable, recurring structural motif not present in the training data (e.g., a metavalent bonding configuration).

- Geometry Optimization: Relax the isolated candidate structure using the MLIP to its local energy minimum.

- DFT Relaxation: Perform a full DFT ionic relaxation (with tight convergence criteria) on the MLIP-optimized structure.

- Property Comparison: Calculate and compare key properties between the MLIP and DFT results:

- Lattice parameters/volume (within 2% agreement).

- Cohesive energy (within 20 meV/atom).

- Phonon dispersion spectrum (ensure no imaginary frequencies for stability).

- Phase Characterization: Perform a DFT-based NVT MD simulation (∼10 ps) at 300 K to confirm the dynamic stability of the predicted phase.

Visualization of Key Methodologies

Active Learning Loop for OOD Mitigation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Tools for OOD Research in MLIPs for PCMs

| Item / Solution | Function & Relevance | Example/Provider |

|---|---|---|

| MLIP Software Framework | Provides architectures (e.g., message-passing networks) and training loops essential for building models capable of UQ. | MACE, NequIP, Allegro, AMPtorch |

| Ab Initio Calculation Suite | Generates the ground-truth data for training and validating MLIP predictions on OOD structures. | VASP, Quantum ESPRESSO, ABINIT, CP2K |

| Uncertainty Quantification Library | Implements methods (ensemble, dropout, evidential deep learning) to calculate predictive uncertainty during simulation. | EpistemicNet, ASAP (ASE-based), custom PyTorch/TensorFlow code |

| Active Learning Management Platform | Automates the loop of simulation, UQ, selection, and DFT labeling. Crucial for Protocol 3.1. | FLARE, JAX-MD, custom scripts with ASE |

| High-Throughput Computing (HTC) Scheduler | Manages thousands of parallel DFT jobs required for labeling OOD candidates in active learning. | SLURM, PBS Pro, AWS Batch |

| Phase & Structure Analysis Tool | Analyzes MD trajectories to identify and characterize new structural motifs (RDF, coordination, bonding). | OVITO, pymatgen.analysis, MDAnalysis, SOCS |

| 1-Methoxy-1-methylcyclohexane | 1-Methoxy-1-methylcyclohexane|CAS 34284-44-1 | 1-Methoxy-1-methylcyclohexane (CAS 34284-44-1) is a tertiary ether for chemical mechanism research. For Research Use Only. Not for human or veterinary use. |

| 6-Methylhept-6-en-2-ol | 6-Methylhept-6-en-2-ol, CAS:32779-60-5, MF:C8H16O, MW:128.21 g/mol | Chemical Reagent |

Machine-learned interatomic potentials (MLIPs) are transforming the discovery and characterization of phase-change memory (PCM) materials, such as Ge-Sb-Te (GST) alloys. The predictive accuracy and computational efficiency of an MLIP are directly contingent on the quality and quantity of its training dataset—the curated set of atomic configurations with associated energies, forces, and stresses, typically derived from expensive ab initio calculations. This document outlines protocols for constructing such datasets in a cost-effective, strategic manner to accelerate PCM materials research.

Foundational Strategies for Data Curation

Active Learning (AL) for Iterative Dataset Construction

Active learning minimizes the number of required ab initio calculations by iteratively selecting the most informative configurations for labeling.

Protocol: Committee-Based Active Learning Workflow

- Initialization: Generate a small, diverse seed dataset (~100-200 configurations) using ab initio molecular dynamics (AIMD) at various temperatures/pressures across the phase space of interest (e.g., crystalline, amorphous, and liquid GST).

- Model Committee Training: Train an ensemble (committee) of 3-5 MLIPs (e.g., MACE, NequIP, SNAP) on the current dataset.

- Candidate Pool Generation: Perform extensive classical or MLIP-driven molecular dynamics (MD) simulations on candidate PCM materials to generate a large pool of unlabeled atomic configurations (10^4 - 10^5 configurations).

- Query by Committee (QBC): For each configuration in the pool, calculate the disagreement (e.g., standard deviation) in predicted energy/forces among the committee models.

- Selection & Labeling: Select the top N configurations (e.g., N=50) with the highest committee disagreement. Perform ab initio calculations (DFT) to obtain accurate labels for these configurations.

- Update & Iterate: Add the newly labeled data to the training set. Retrain the committee and repeat steps 3-5 until model error metrics (forces RMSE, energy MAE) converge below a pre-defined threshold.

Diagram 1: Active learning workflow for MLIP training.

Data Augmentation via Symmetry and Perturbation

Maximize the informational value of each expensive ab initio calculation.

Protocol: Symmetry-Adapted Perturbative Augmentation

- Symmetry Expansion: For each calculated DFT configuration, apply all symmetry operations of the space group (for crystals) or random rotations/inversions (for amorphous/liquid) to generate symmetrically equivalent copies. This is intrinsic in modern invariant MLIPs.

- Perturbative Displacement:

- For each configuration, generate 5-10 perturbed copies by randomly displacing all atomic positions with a normal distribution (σ = 0.01-0.05 Å).

- For each perturbed copy, use the ab initio calculated forces to approximate the energy of the perturbed configuration via a first-order Taylor expansion: ΔE ≈ -Σi fi · Δr_i. This provides approximate energy labels without new DFT.

- Strain Application: Apply small random strain matrices (deviatoric and volumetric, up to ±3%) to the simulation cell to augment stress tensor data.

Quantitative Benchmarks & Cost Analysis

The following table summarizes the impact of curation strategies on model performance for a representative PCM material, Geâ‚‚Sbâ‚‚Teâ‚…, based on recent literature.

Table 1: Impact of Data Curation Strategy on MLIP Performance for GST-225